CTI Industries, Inc. is a service company that specializes in steam condenser and heat exchanger repair.

In 1976, CTI developed a tube repair technique that today is recognized as the most widely used cost-effective system in the world. The thin-walled tube insert, the CTI Shield/SealsTM propelled our success in offering cost-effective solutions for equipment life extension.

CTI offers two basic types of sleeving for the repair of condensers and heat exchangers.

Besides condensers, these patented tube repair techniques have successfully been applied to a wide variety of exchangers – fin-fan air coolers, process shell-and-tube exchangers, hydrogen coolers, HP feedwater heaters and many more.

For those units suffering from inlet-end erosion, Stress Corrosion Cracking, crevice corrosion or any problems related to the tube-ends, CTI offers its most cost-effective tube repair, the CTI Shield/Seal™, also known as a tube insert or ferrule. Although Shields are typically only 6″ – 12″ long, some applications have required Shield lengths up to 14 feet!

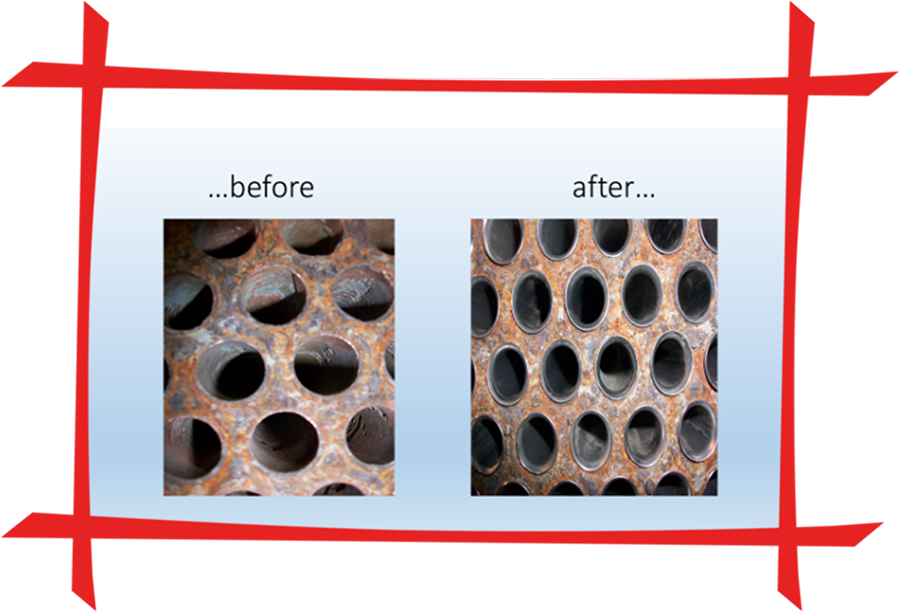

CTI Industries, Inc. developed its patented Shield/Seal” repair for condenser and heat exchanger tube in 1976. The repair technique involves the installation of thin-walled alloy inserts – CTI Shield/ShieldsTM – into damaged tube ends. The “Shields” are fabricated from a variety of erosion resistant alloys based on the parent tubes and their failure mechanism. Tube ends are cleaned, the Shields installed and expanded into the existing tubes. The Shield/Seal repair method can save up to 90% versus the cost of traditional retubing.

Unfortunately, some exchangers suffer from full-length problems. In this case, CTI Full Length Tube Liners™ can be a very attractive alternative to a partial or full retube.

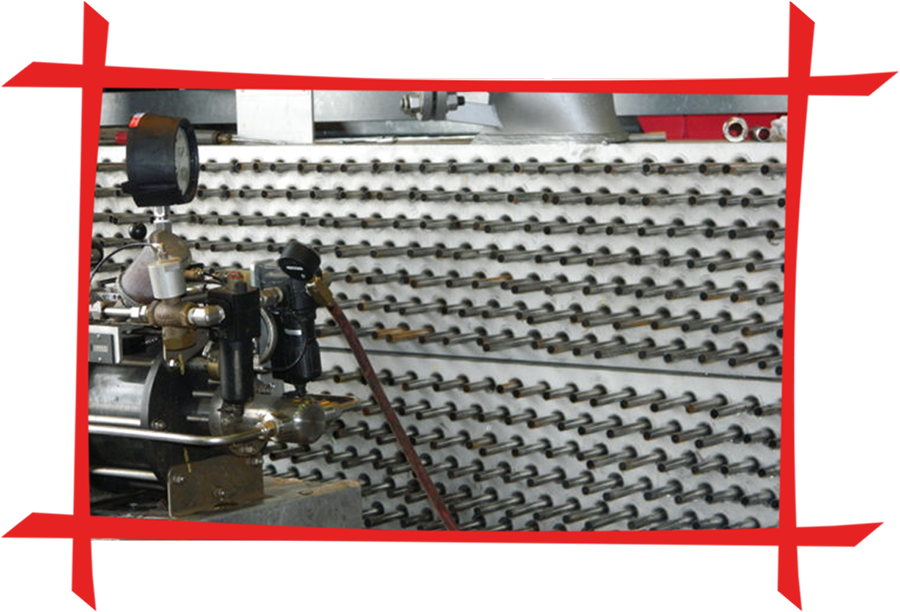

Tube LinersTM – another restoration process patented by CTI. The “liners” are thin walled tubes selected from a number of different alloys. Plugs are removed, tube I.D.’s cleaned and liners installed. They are then hydraulically expanded to intimately fit the existing tubes, ensuring maximum heat transfer. Finally, the liners are trimmed flush and mechanically expanded at the tube sheet areas resulting in a fully restored tube.

CTI has also developed the technology for repairing failing or plugged tubes with Full Length

CTI has installed more than 5 million Shield/SealsTM in 32 countries around the world. Our Customers include electric utilities, refineries, commercial marine, desalination plants, paper mills and other industrial sites. Shield/Seals are used exclusively on board U.S. Navy Ships, from frigates to aircraft carriers.