Improving Burner Efficiency—For Safety and Efficiency

The emphasis on safety in the design and operation of direct-fired heaters has steadily increased in the last two decades—and the technology relating to electronic control and automated operation of burners has evolved with it.

With the opportunity to fine-tune burners plant engineers can not only increase safety but also improve efficiency and lower fuel costs.

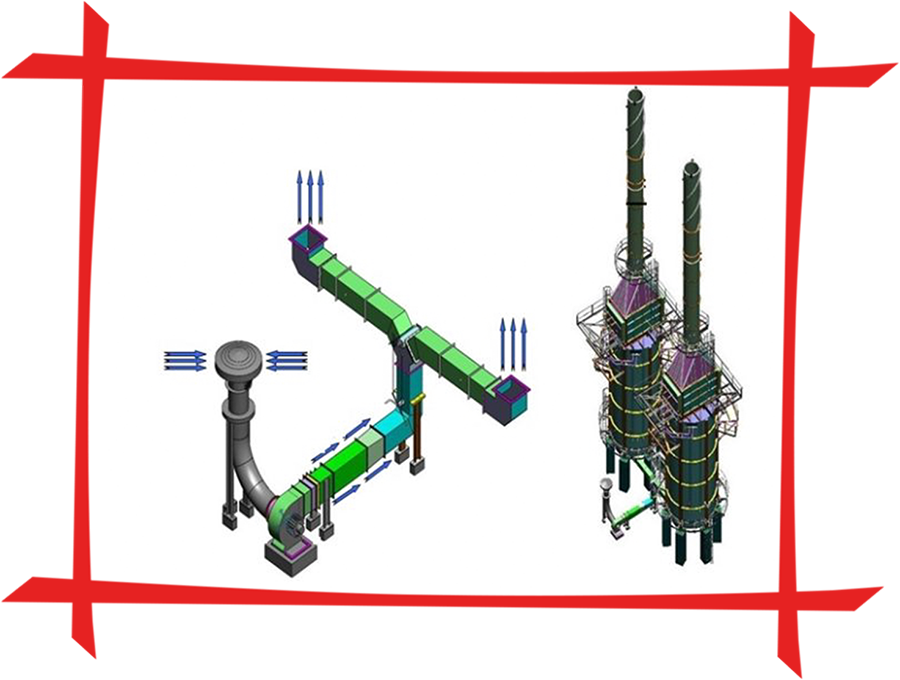

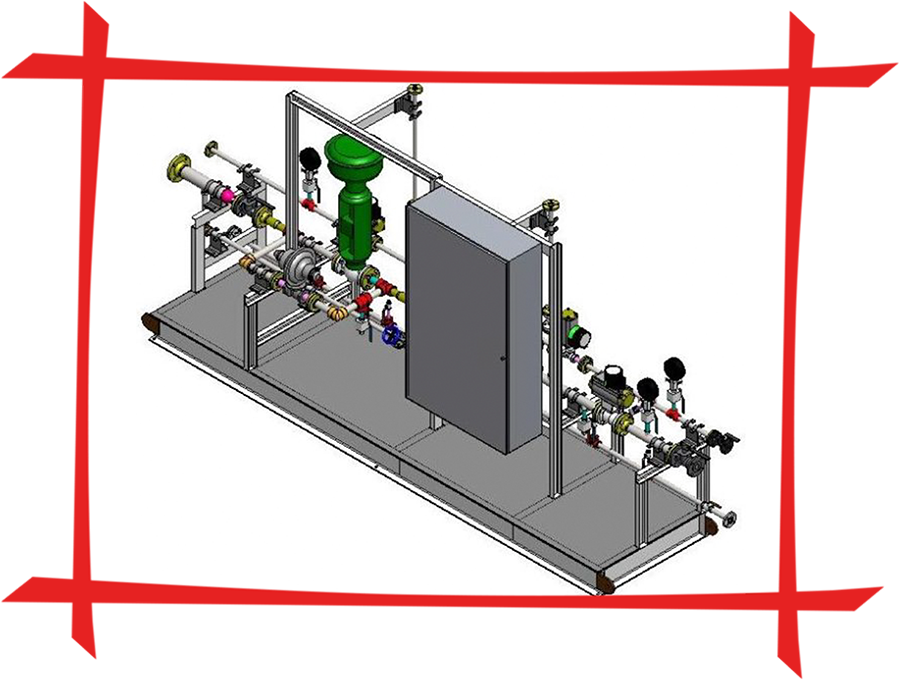

Typical Revamp will include the following activities:

Review of existing P&ID and As built document

- Identify minimum requirement for a BMS as per NFPA 87 and other project specification guideline.

- Establish Project revamp objective

- Design and detail Engineering

- Attend HAZOP and SIL study

- Supply of components like Independent flame scanner, Auto ignition System, Independent fuel isolation system and implementation of auto heater purge system, PLC based BMS.

- Installation and commissioning assistance.

The most important function of the BMS is to prevent the possibility of an accumulation of combustible gas within the Heater, prior to introducing a flame inside the Heater.

To accomplish this, ambient air is drawn into the Heater and expel or “purge” any combustible gases to the atmosphere.

Recent changes in safety regulations now dictate that a timed purge has to be determined and that there has to be a means to prove that there have been a minimum of four air volume changes in the Heater prior to ignition.

Project costing for revamps and retrofits is also strength of our experienced revamp team. We base our cost estimates on a practical assessment of potential field costs for the project scope, relying on our significant experience in this type of work.